Our Story

Founded in 1978 by Chris F. Fette, TESCO began with a simple mission: to provide the highest quality maintenance and repair tooling available, while continually innovating to meet the changing needs of our industry.

By 1981, our growth led to the establishment of our first manufacturing facility. In 1985, we established a machine shop to ensure tighter control over our manufacturing process and guarantee quality at every stage. In 1989, we acquired a local class-A weld and fabrication shop, allowing us to complete the entire manufacturing process in-house.

Since then, we have invested heavily in technology and training. Our machine shop now features nine advanced CNC machines and several manual stations. Our weld shop is equipped with state-of-the-art equipment, and all welders hold Structural Certification.

What We Do

Today, TESCO manufactures and distributes over 3,000 different tools, including:

- Torque adapters

- Torque wrenches

- Hydraulic and pneumatic tools

- Specialty fixtures

- Heavy-duty lifting equipment

We proudly serve every major domestic railway and hundreds of railways worldwide. Our close involvement with safety committees allows us to develop tools that enhance productivity and promote safe work practices in line with OEM-specified procedures.

Our Facilities

Manufacturing

Our entire operation is housed in a 66,000 square-foot facility, including a modern 6,000 square-foot office.

The manufacturing bay is equipped with three 10-ton overhead cranes, while our fabrication area features a custom jib crane/monorail system designed to handle even the most challenging materials.

Machining and Fabrication

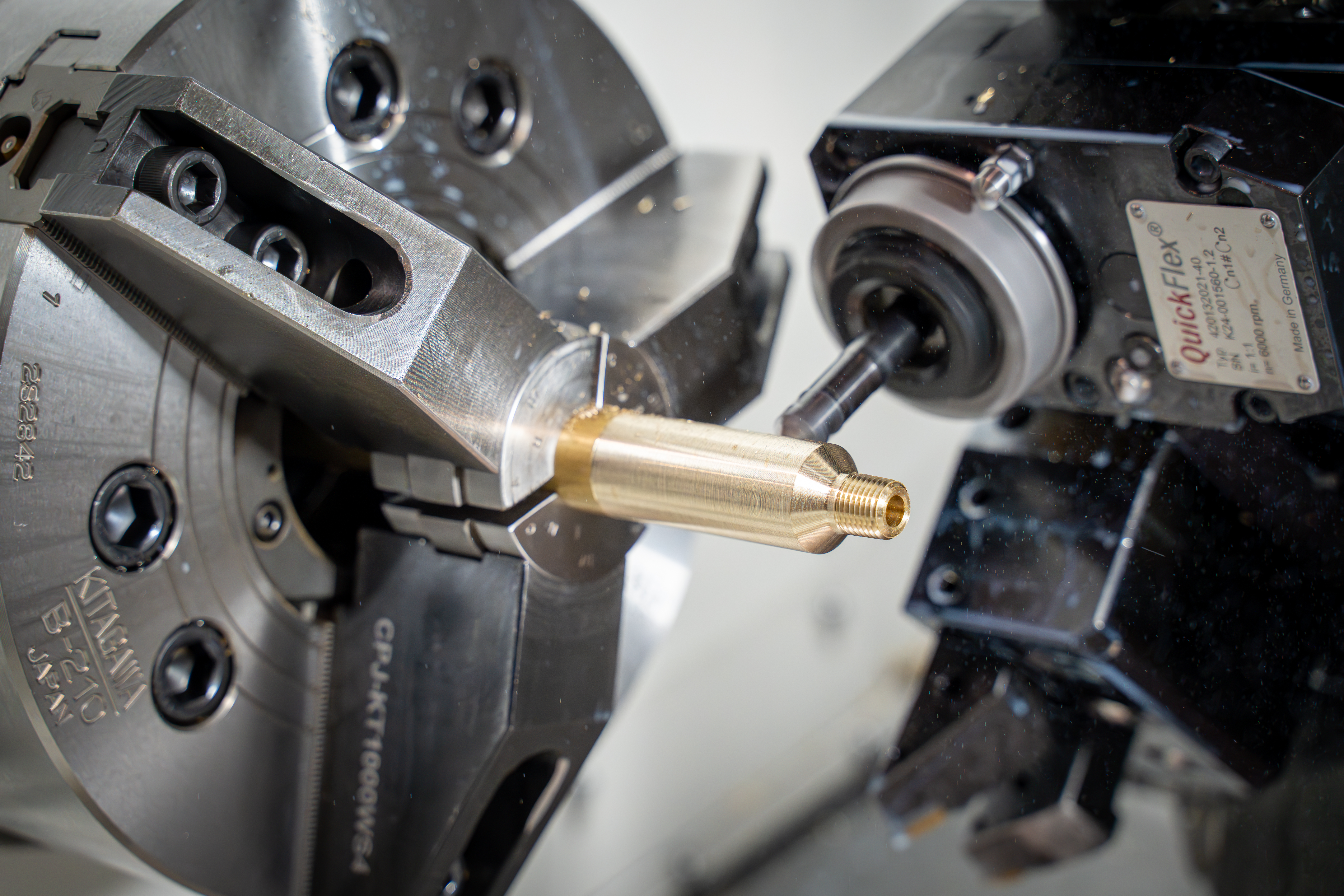

Our machining center includes eight CNC machines, as well as a full suite of manual mills and lathes. We continually upgrade our resources to stay at the forefront of industry standards.

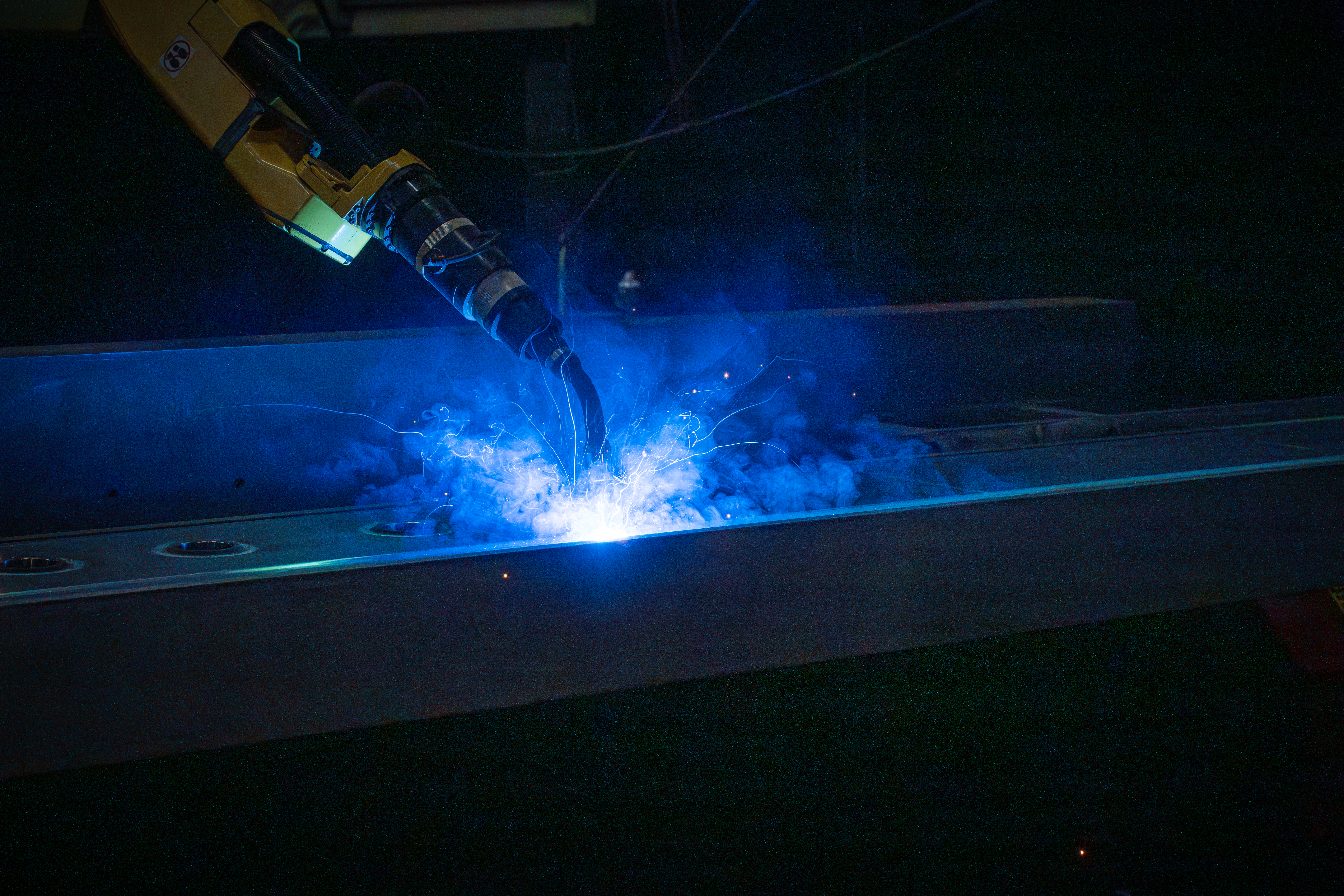

Our fabrication facility features three TIG and three MIG welding stations, a CNC plasma burn table, and a Lincoln Electric robotic welder.

Quality Assurance

We maintain a custom certification platform with fixtures capable of certifying under-the-hook lifting devices to well over 150,000 lbs.

All special assembly work is performed in a clean room environment to prevent contamination and ensure the highest quality.